Foam Protection for the Gulf Coast

Design, installation, and service of foam suppression systems for high-hazard environments.

Who We Help

Industrial Facilities & Refineries

Operations with flammable liquid hazards that need specialized foam suppression—engineered to control fast-spreading fuel fires.

Shipyards & Maritime Facilities

Docks, vessels, and fuel storage areas where foam is required—built for coastal exposure, salt air, and demanding site conditions.

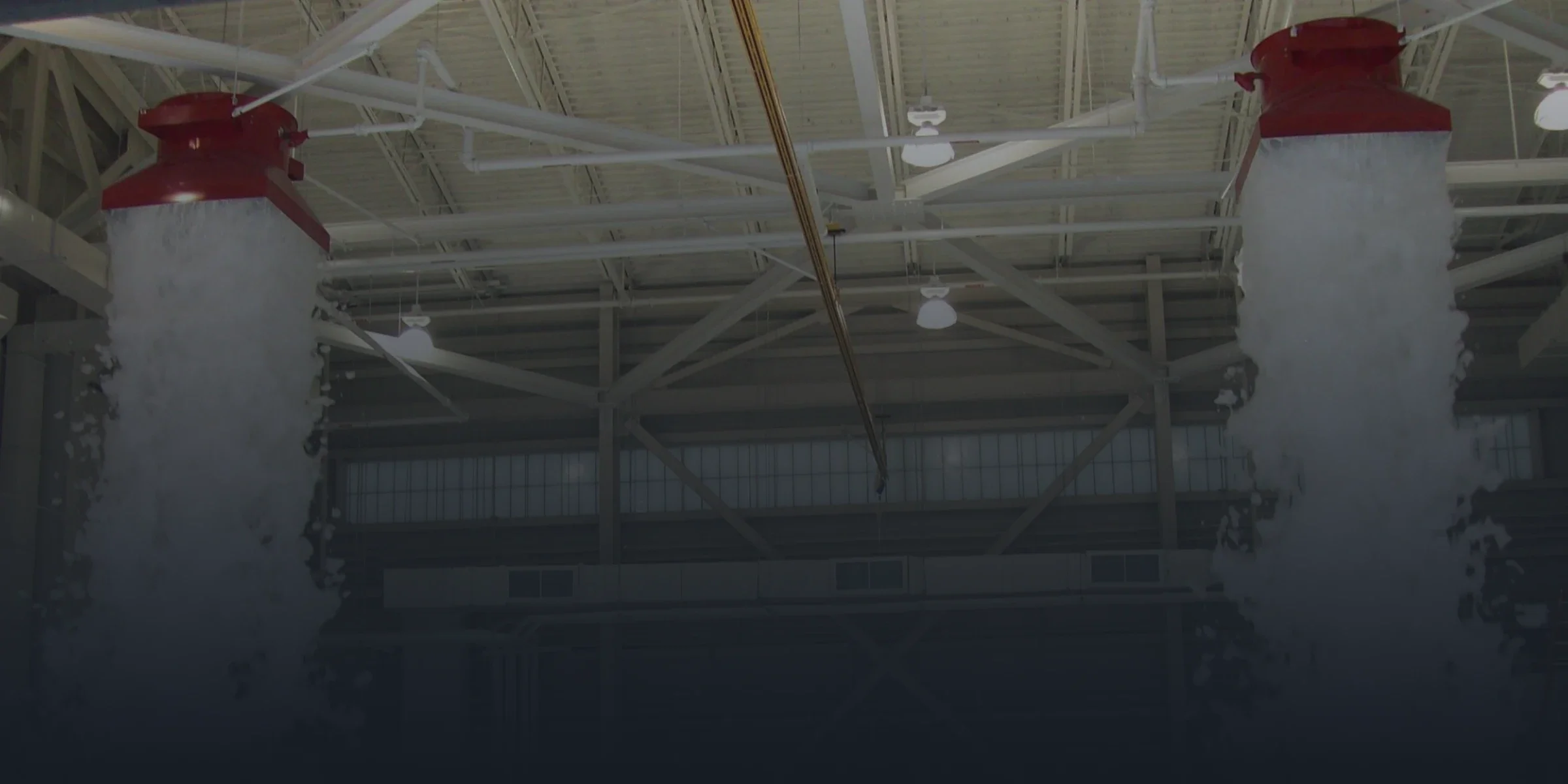

Aviation Hangars & Terminals

Facilities requiring foam fire protection for compliance and readiness—designed to meet NFPA 409 expectations for aircraft hazards.

What You Get

End-to-end foam system solutions—engineered, installed, tested, and maintained to protect high-hazard sites and keep you inspection-ready.

Foam System Design – Engineered layouts with proportioning, storage, and distribution tailored to your hazards, fuel loads, and application needs.

Installation – NICET-certified crews installing foam chambers, generators, and delivery systems with clean workmanship and clear site coordination.

Testing & Commissioning – Foam concentrate acceptance, proportioning tests, and discharge verification so systems are proven, documented, and ready to pass.

Inspection, Testing & Maintenance (ITM) – Recurring service programs per NFPA 11, 16, and 409 to keep systems compliant, reliable, and documented.

Retrofits & Upgrades – Updates to existing foam systems for code compliance, modern concentrates, and changing hazard requirements.

Specialty: Foam systems for fuel storage, aircraft hangars, and coastal industrial hazards.

Why ICFP Foam Systems

Hazard-focused expertise, code-driven performance, and clean workmanship—built for Gulf Coast industrial risks and inspection expectations.

Hazard-focused expertise

We design and install foam systems for refineries, hangars, fuel storage, and shipyards—where water alone isn’t enough.

Code-driven performance

NFPA 11, 16, and 409 requirements are built into design, installation, testing, and ongoing service.

Local knowledge

From Slidell through Picayune and up to Hattiesburg—we understand the facilities and hazards that require foam across the Gulf Coast region.

Workmanship that stands out

Systems are installed clean, labeled, and organized—so operations teams can own them and inspectors can verify them quickly.

Lifecycle service

From design to install to ITM, repairs, and retrofits—we keep foam systems ready to perform when needed.

New Foam System Design & Install

- Hazard and fuel load analysis

- Foam concentrate selection and storage design

- System layout and installation (proportioning + distribution)

- Proportioning and discharge testing

Foam System Testing & Maintenance

- Annual proportioning and discharge tests

- Concentrate quality verification

- Retrofits for new foam agents (fluorine-free, etc.)

- Repairs and upgrades

Industries We Serve

Our Foam System Process

From discovery to compliance

- Discovery Call – Review hazard, fuel type, and compliance requirements.

- Design & Engineering – Select concentrate and engineer system layout.

- Installation – Install proportioning, storage, and distribution equipment.

- Testing & Commissioning – NFPA-required proportioning and discharge tests.

- Maintenance – Scheduled inspections, testing, and concentrate verification.

Outcome

FAQ

-

Yes. We upgrade proportioning systems and replace outdated foam agents.

-

Yes. We verify foam quality and proportioning per NFPA standards.

-

Yes. We design and install hangar foam systems per NFPA 409.